Turf[TECH]Report: CRN: Controlled Release Nitrogen - What you don't know could BURN your turf!

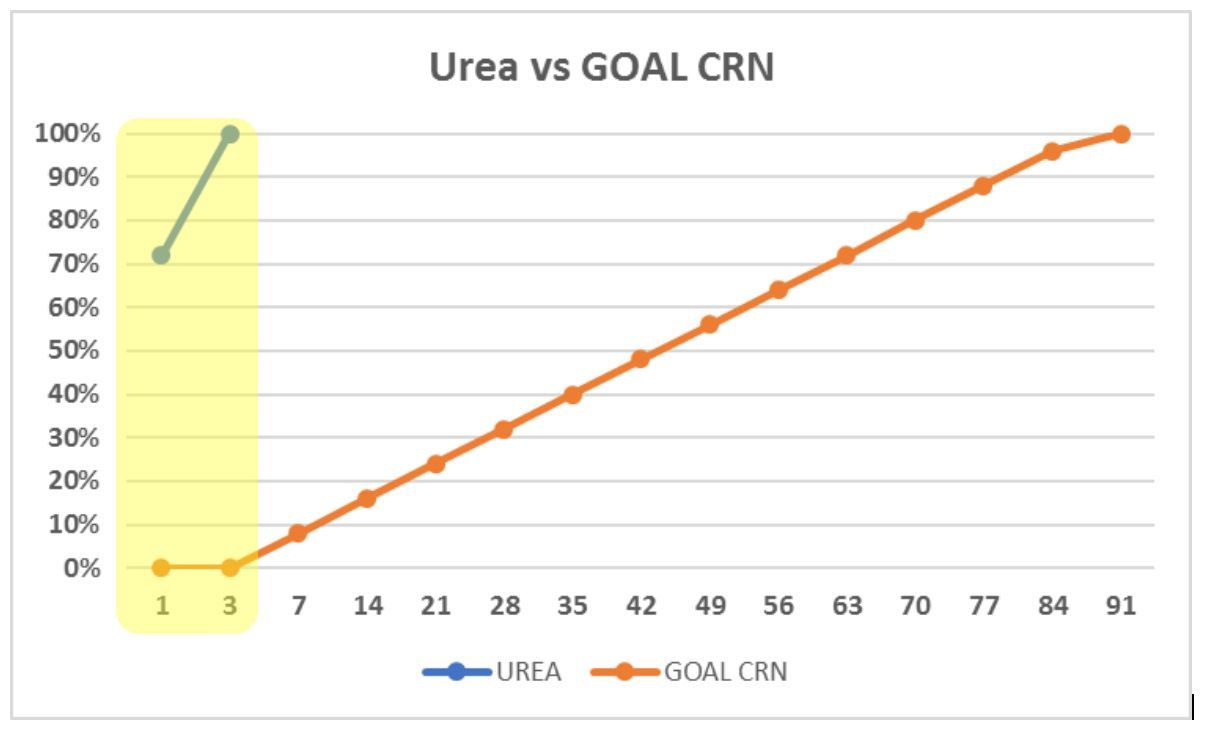

Urea vs. GOAL CRN (chart 1): Note that in this chart, urea is depleted within the first 3 days of being applied to the ground. This is why manufacturers strive to create CRN products that don’t release any nitrogen until shortly after straight urea has been depleted.

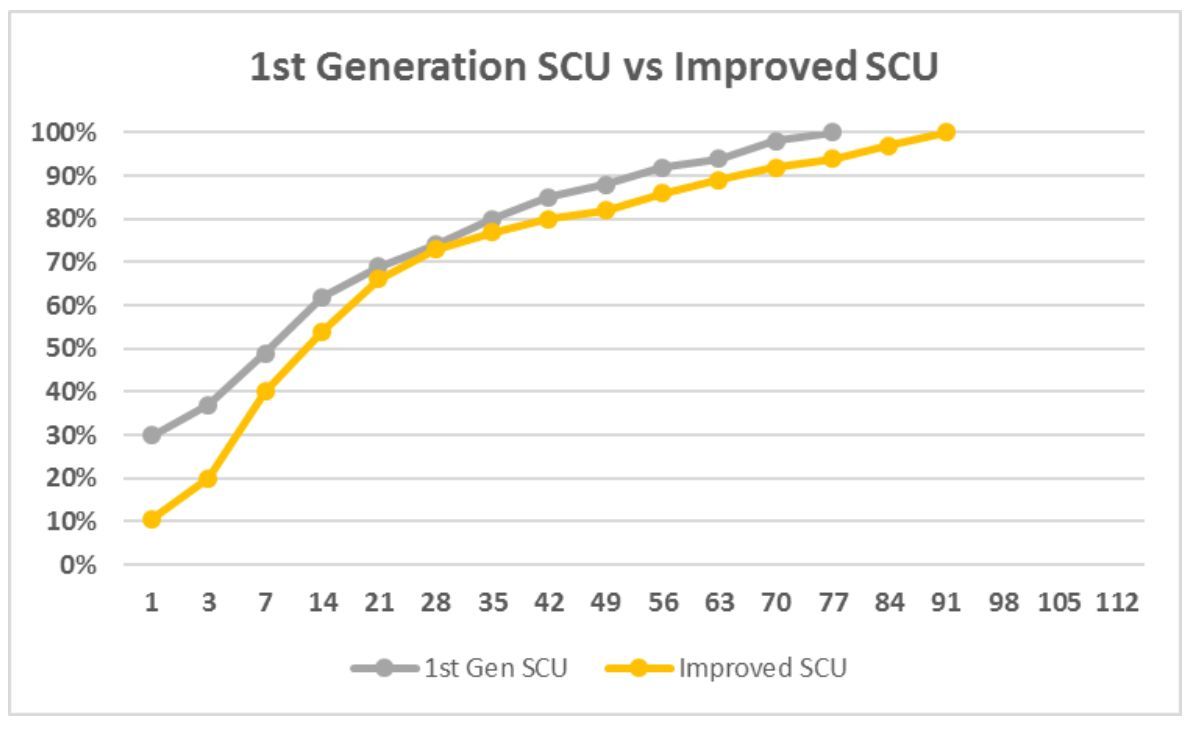

1stGeneration SCU vs. Improved SCU (chart 2): Note that 1stGeneration SCU products typically release up to 30% of their nitrogen within the first few days; this is undesirable as most fertilizer blends already have straight urea in them. Improved SCU products demonstrate a nearly 20% reduction in nitrogen release in the first few days; this is desirable. Why pay a premium for CRNs that behave like straight urea within the first few days of their application?

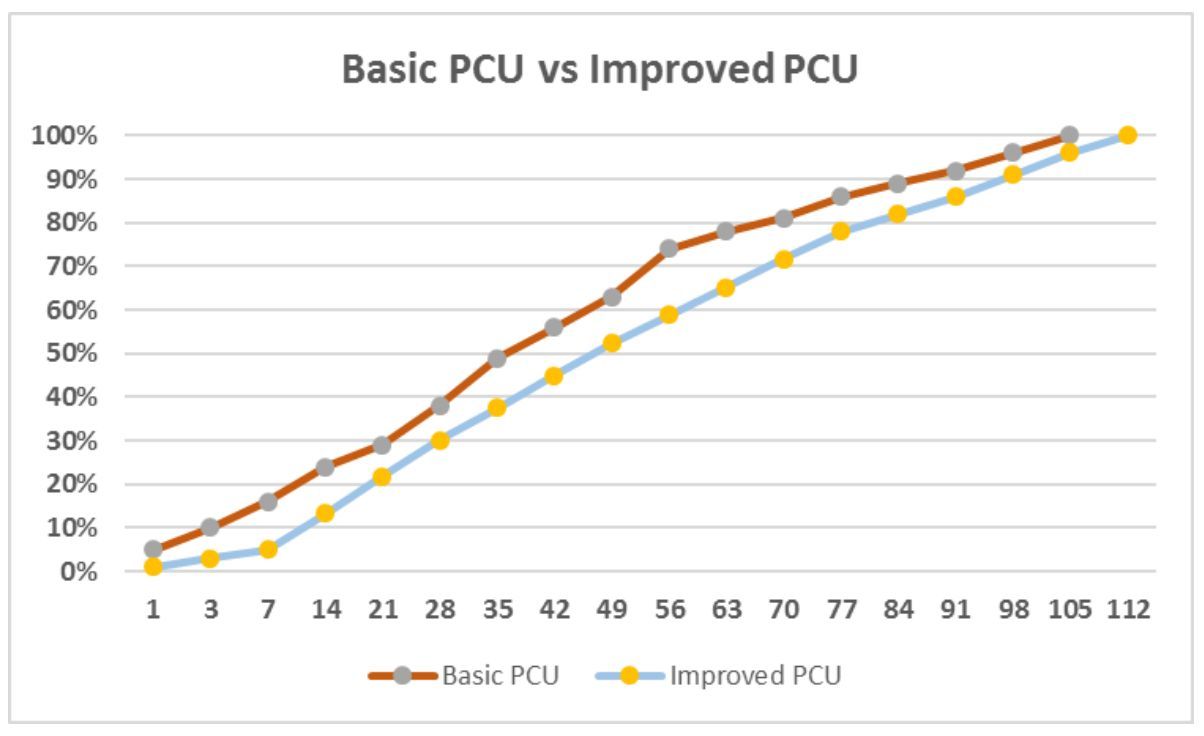

Basic PCU vs. Improved PCU (chart 3): Note that with improved PCU, nitrogen release is delayed within the first week (this is desirable), and that the overall release curve is much straighter than that of basic PCU. Many improved PCU products now last well beyond 90 days with consistent and predictable nitrogen release week to week.

THE EVOLUTION OF CRNS OVER TIME Take a look at the dissolution rate curves in the graph above. These curves do not represent specific CRN products, but rather demonstrate the evolution of classes of CRN products over time. First, note that straight urea (46-0-0) releases nearly all of its nitrogen within 3 days under normal conditions (chart 1). Urea is the best source of nitrogen on a cost per ton basis, hence urea is the base raw ingredient for nearly all CRN products.

Next, look at (chart 2) basic SCU (invented in the late 1960s). Note that basic SCU releases nearly 30% of its nitrogen within the first day or two. Its release curve mimics a standard logarithmic curve, meaning compared to other CRNs, it releases more of its nitrogen earlier in the curve. Given this challenge (too much nitrogen release within the first few days), manufacturers and agronomists were determined to reduce this initial nitrogen load into the ground. This led to the development of polymer coated urea (PCU) several decades later. In addition to quelling the early nitrogen release problem associated with first generation SCU, PCU also brought straighter, more consistent release curves to the industry (chart 3). Today’s improved PCU products have release curves that mimic a shape of a hockey stick, resulting in more gentle transitional nitrogen feeding for turf. Improved PCU products have also been engineered to reduce lock-off issues, and last longer in the field.

Last, the higher costs associated with components and manufacturing improved PCU products has led to the development of improved or “enhanced” SCU products. Improved SCU uses hardeners and or polymers and or waxes to mitigate the early nitrogen release issues associated with 1stgeneration SCU products. Improved SCU products are also more resistant to abrasion and have longer release windows. Some improved SCU products now last as long as 90 days in the field.

HOW DO I CHOSE THE RIGHT CRN FOR ME?

Choosing the right CRN comes from an understanding the dissolution rate (or release curve profile) of each CRN, and then deciding which CRN gives you the nitrogen you need when you need it. For example, an applicator who only likes to drop fertilizer in the spring may want to pay a premium for a 180-day CRN, that way he or she only has to fertilizer once per year. In most cool season grass climates, a 180-day product will make it through most of the growing season (year to year variations in weather will affect the performance of a 180-day product). Conversely, a lawn care business might prefer a 45-day product such as XCU, due to sporadic weather conditions, financial factors, specific agronomic / control programs, etc. This isn’t necessarily a bad thing for lawn health either; more nitrogen is making into soil and being taken up by the plant per year than dropping a 180-day product only once per year. You should pick your CRN product based on how it fits into your turf maintenance program. For example, if you only fertilizer twice per year, two 90-day products might be right for your situation. If you’re a golf course superintendent, you might prefer to “spoon-feed” your turf, which means you might want to use 30-day products 5-8 times per year. It all depends on your climate and the nature of your turf maintenance program.

WHAT ARE THE EFFECTS OF APPLYING LOW-QUALITY CRN PRODUCTS TO TURF?

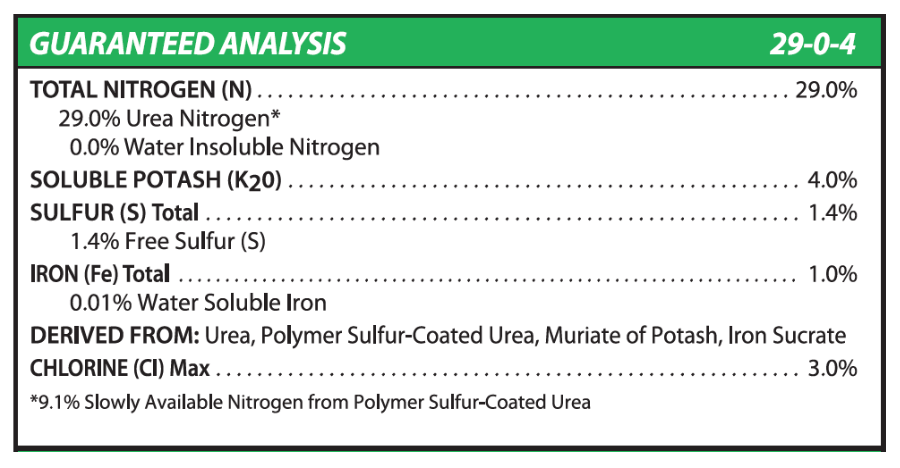

The whole concept behind CRN products is that they release nitrogen slowly and evenly over time. Low quality coatings are more susceptible to fracturing through abrasion (the colliding of CRN granules against each other during storage and transport). This is why most CRN products guarantee up to about 90% of their slow-release integrity on the bag. (What this means is, if you had a 50 LB bag of pure 39-0-0 SCU, about 10% of the bag would be considered ‘immediate release’ due to the fracturing of about 10% of the SCU granules during storage and transport. Fractured coatings are considered ‘compromised’ and are treated the same as straight urea from a labeling standpoint.) Low-quality CRN products run the risk of behaving like straight urea, which means they have the potential to burn or even kill a lawn. Before purchasing any CRN, ask for dissolution rate data and don’t hesitate to dig into that product’s industry reputation.

For professional fertilizers, humic and AMP-XC™ enriched products available, please visit TurfCare’s online Product Catalog.

For green industry professionals or others interested in ordering Turfcare products, please contact our Customer Service to find a distributor near you.

The TURFReport Highlights:

Additional Articles and Insights